Question: I found a moldy patch of drywall. Can I just spray it with a mold-killing product and wipe it away?

The Short Answer:

Unfortunately, simply spraying mold growth on porous or semi-porous building materials, such as drywall or wood, is often ineffective and even unsafe.

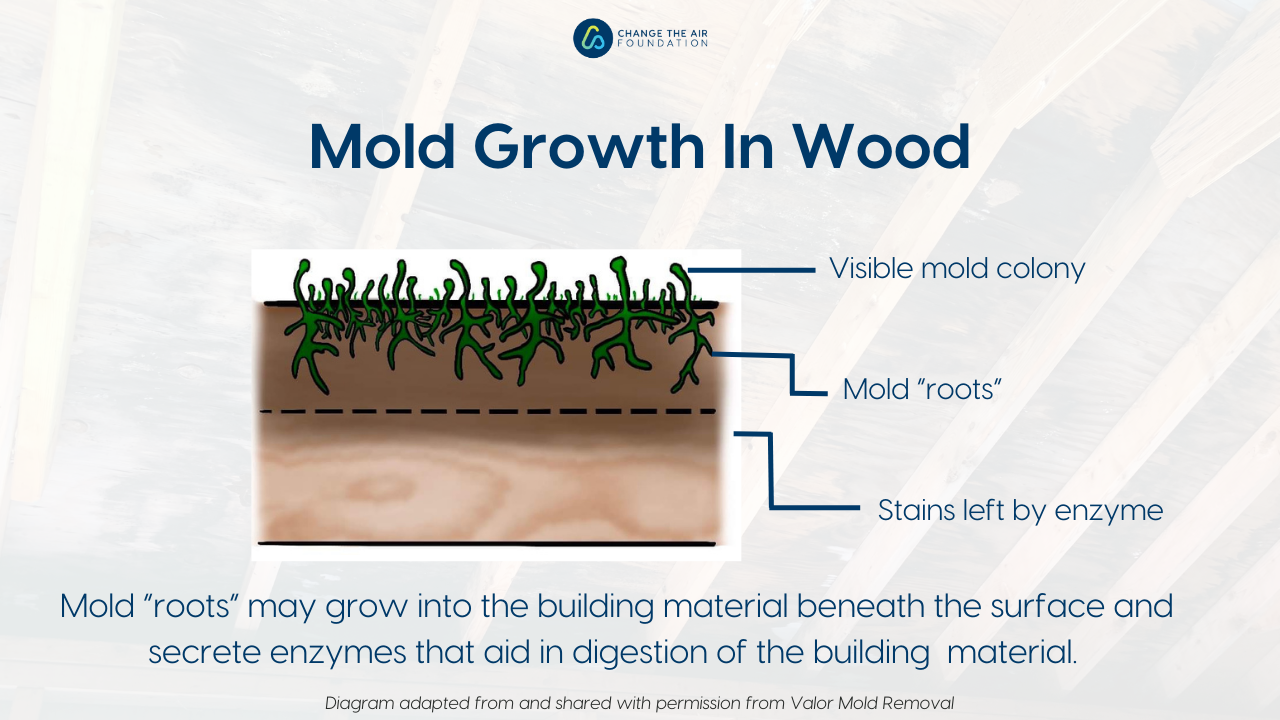

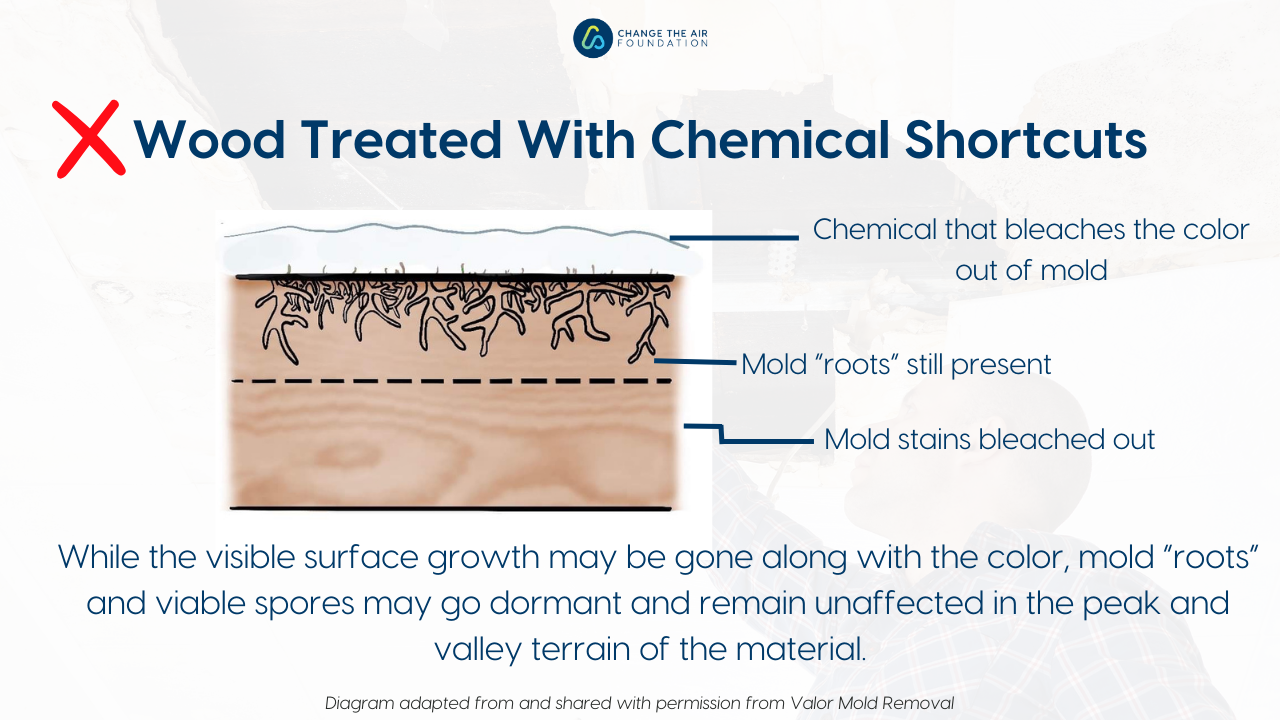

Research has also shown that many products—including bleach, hydrogen peroxide, isopropyl alcohol, and even commercial “mold removers”—only treat what is on the surface. These products may fade stains or remove visible growth, but they can’t reach deep enough into the material where mold mycelia (the “roots”) have grown.¹ As a result, when conditions become favorable again, the mold can easily grow back.

Additionally, “dead” or dormant mold still poses health risks², and many of the harmful byproducts created by mold, such as mycotoxins, aren’t living organisms, so they can’t be “killed”.³ Finally, spraying or disturbing mold growth can release tens of millions of spores, fungal fragments, and mycotoxins into the air, while also exposing the building occupants to the odors and residues of potentially harmful chemicals that remain behind.⁴

Bottom line: No “spray and pray”! Mold remediation should always focus on safe and effective removal, never “killing.”

The Long Answer:

To understand why chemical shortcuts aren’t very effective and, in some cases, are dangerous, it’s important to first understand what you are trying to remove and the limitations of chemical cleaners on many building materials.

A Look at the Life Cycle of a Mold Spore

What follows is a simplified explanation of the mold life cycle. In order to understand why chemical shortcuts often fail to properly address the issue, you must first understand how mold grows.

By the time you see visible mold growth in your home, much has already been happening above and below the surface. All it takes for a colony to develop is a single spore, enough moisture, and a food source. Unfortunately, many common building materials found in homes, such as drywall, carpet, and wood, make excellent food sources for mold and other microbial growth, such as bacteria.

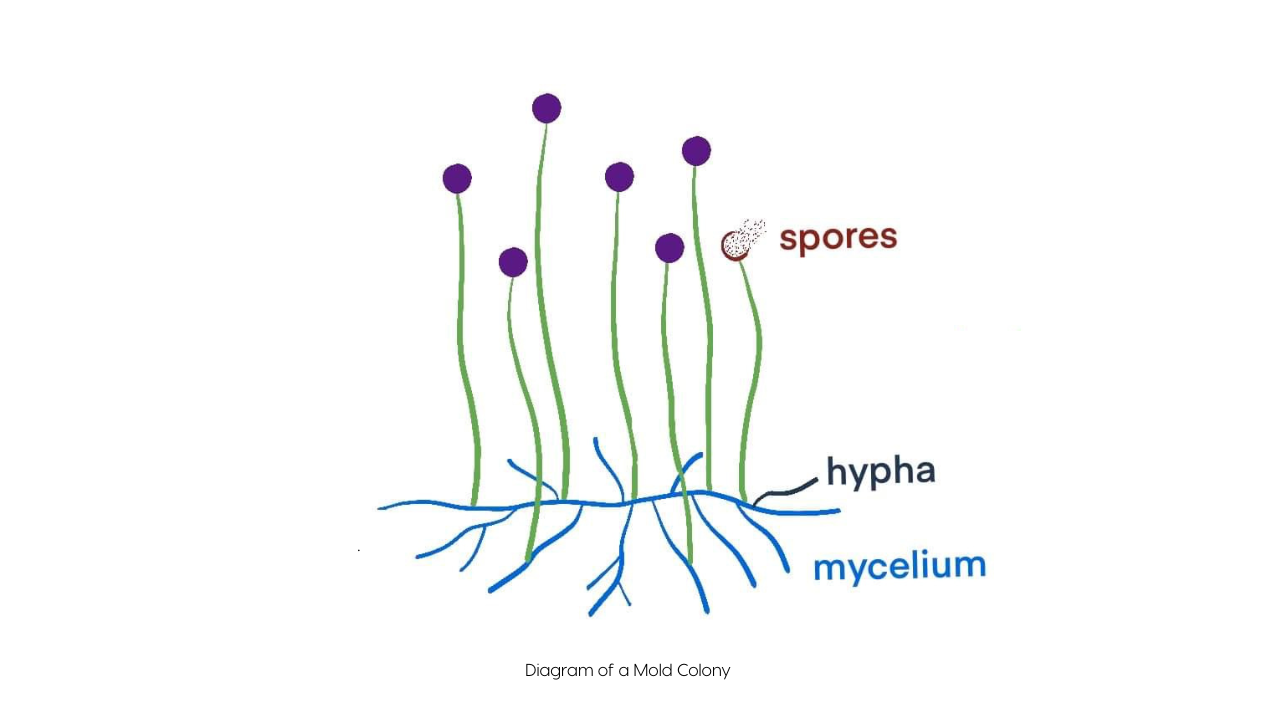

Once a spore finds the right conditions, it begins to germinate. From there, it produces root-like structures called hyphae (plural of hypha). A collection of hyphae, known as mycelium, forms a mat that spreads throughout the material. As the colony matures, it eventually produces and releases new spores, which are seed-like particles that can spread to surrounding areas and allow the life cycle to continue.⁴ You can learn more about the life cycle of mold in our interview here.

But spores aren’t the only byproduct of mold growth. A growing colony also produces primary metabolites such as microbial volatile organic compounds (mVOCs). These gases are released when mold actively feeds and digests materials. Because of their odor, some people jokingly refer to them as “mold farts”. You can learn more about mVOCs in our interviews here and here.

Certain molds, under specific conditions, can also produce secondary metabolites such as mycotoxins. Mycotoxins are poisonous chemicals designed to kill other living things. Their primary purpose is thought to be defense. Much like thorns protect a plant, mycotoxins help mold defend itself against other invading molds and bacteria. It is important to note that mycotoxins aren’t living organisms and therefore can’t be “killed.” Mycotoxins aren’t gases, either. If mycotoxins are produced, they ooze over parts of the mold colony and even the immediate surrounding building materials, similar to how lava oozes over a volcano. Mycotoxins can’t multiply on their own and are only produced by living mold colonies. That said, if a colony has produced mycotoxins and then becomes dormant, the mycotoxins don’t magically disappear, they remain and can continue to be an exposure and health risk. You can learn more about mycotoxins in our interview here.

Unfortunately, stopping the moisture source doesn’t eliminate the potential health threat posed by mold growth indoors. A “dead” or dormant mold colony still poses health risks since many of the byproducts produced by mold, such as mycotoxins, fungal fragments, mVOCs, are not living to begin with. Even a non-viable mold spore (one that is not capable of growing) is still a health hazard. The EPA addresses the use of biocides in mold remediation by stating: “Dead mold is allergenic and may cause allergic reactions and other health effects in some individuals, so it is not enough to simply kill the mold. It must also be removed.”² For a more detailed explanation of the complex ecosystem created by mold- and water- damaged buildings, including health effects, see this paper by Dr. Jack Thrasher and Sandra Crawley, and this paper by Dr. Janette Hope.

A Look at Mold Growth in Building Materials

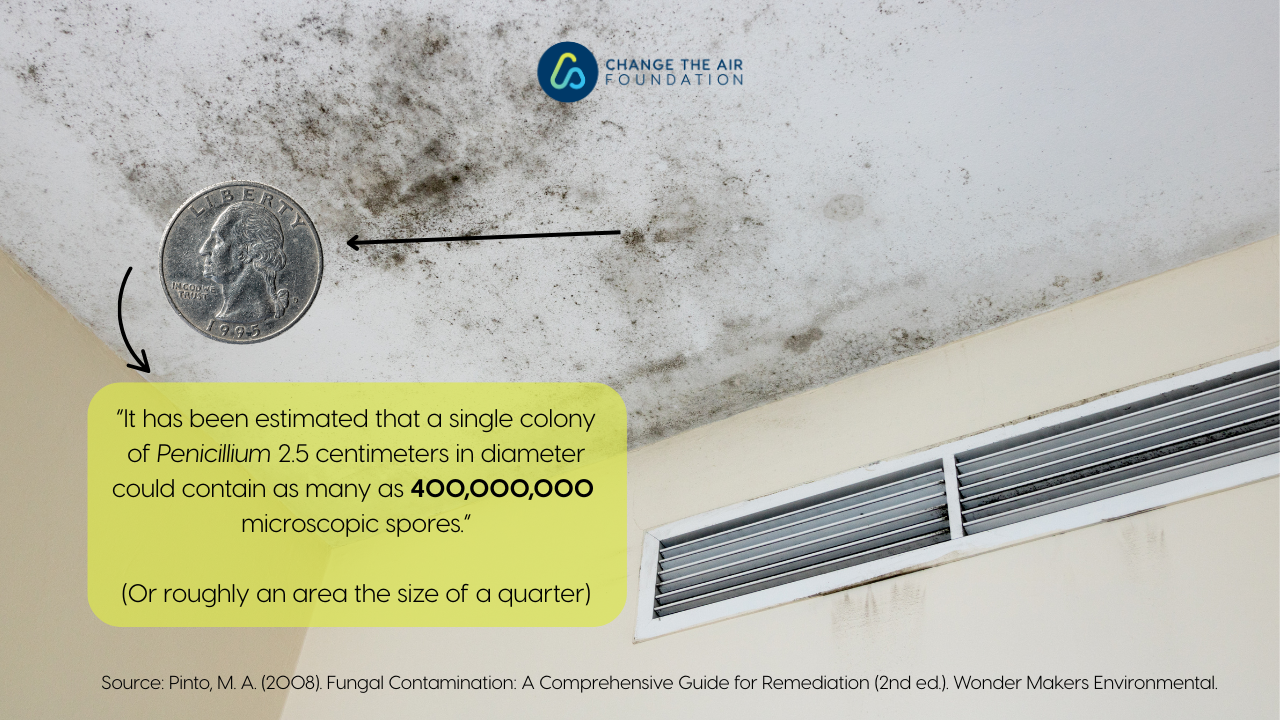

It is not possible to see a single mold spore with the naked eye. By the time you see mold growth, there are likely tens of millions of spores present. To put this in perspective, a 2.5-centimeter colony of Penicillium (about the diameter of a quarter) can contain as many as 400,000,000 spores.⁴

When mold grows on a building material, you may only be able to see what has grown on the surface. What you can’t see is what has grown into or behind the building material. The root-like structures that grow into building materials, such as wood and drywall, secrete enzymes that help the mold digest the material. Not all food sources are ideal for every type of mold. Just like people, different molds prefer different foods. Learn more about different species of mold in our interview here.

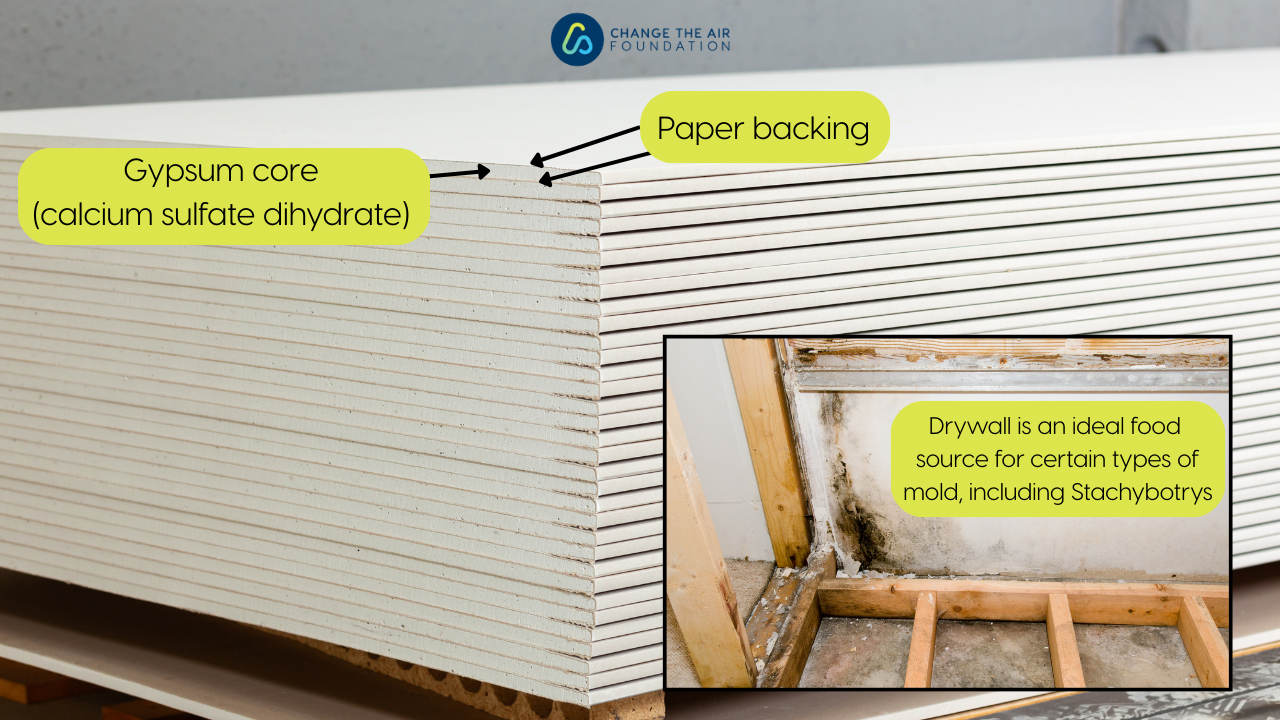

Unfortunately, many of the materials commonly used to build homes in the United States are the perfect food source for mold. It’s just a matter of adding water. Take drywall, for example. Roughly 92% of new construction homes in the U.S. are built using drywall.⁵ Drywall is typically composed of a gypsum core sandwiched between two layers of heavy paper. When drywall becomes wet, it acts a bit like a sponge, holding onto moisture from leaks, floods, or even high humidity. The paper backing contains cellulose, which is an ideal food source for certain types of mold, including Stachybotrys.

But wait, mold needs more than just a food source and moisture to grow—it also needs a spore. Unfortunately, a 2017 study titled “Pre-contamination of new gypsum wallboard with potentially harmful fungal species” found that much of the drywall used in construction comes preloaded, so to speak, with mold spores. The results found “that gypsum wallboard is contaminated with Neosartorya, Chaetomium, and Stachybotrys and suggest that the spores of these fungi are embedded in the paper/cardboard surrounding the gypsum core.”⁶ Simply put, there are likely mold spores already in your drywall; all it needs is moisture for the life cycle to continue.

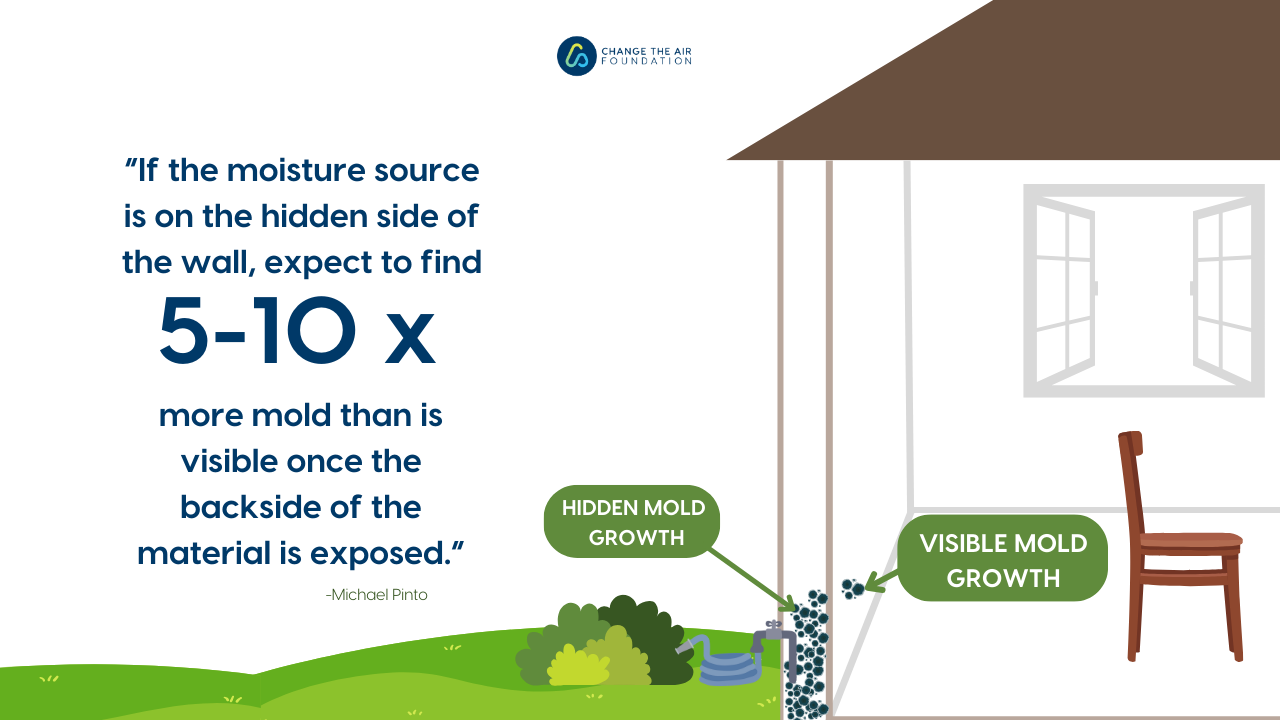

In addition to being unable to easily see what is below the surface, if the moisture source is located behind the building material, you can expect to find 5-10 times more mold than what may be visible.⁴ This is because the environment inside a wall cavity (dark, stagnant air with a built-in food source) can create ideal conditions for mold growth if the area remains damp long enough. Simply put, the backside of a building material (such as drywall) may harbor significantly more mold than the front side. Download your free copy of “Moisture Basics” to learn more.

A Look at the Research on Chemical Treatments on Moldy Building Materials

Many products, whether they are common household cleaners or specifically marketed to “kill mold,” may only remove the visible mold growth from the surface and/or bleach the color from the surface. The chemical solution is often unable to penetrate into the building material where hyphae (mold “roots”) have grown. This is particularly true for semi-porous and porous building materials such as wood, drywall, and oriented strand board (OSB).

A 2013 study titled “Evaluation of Five Antifungal Agents Used in Remediation Practices Against Six Common Indoor Fungal Species” illustrates the shortcomings of chemical-only shortcuts when it comes to mold remediation. Relying on chemicals lull the public into a false sense of security.¹

The study evaluated growth and spore germination on six common indoor molds: Alternaria alternata, Aspergillus niger, Chaetomium globosum, Cladosporium herbarum, Penicillium chrysogenum, and Stachybotrys chartarum. Wood was inoculated with these six molds and then subjected to five different antifungals: isopropyl alcohol, hydrogen peroxide, bleach, and two brand-name products.

The study found: “The inhibitory effect is reversible once the inhibitory substances are removed or become diluted; spores again become viable and mycelia can resume growth. Most of the fungicides are effective only on hard non-porous surfaces. Viable spores hiding in porous surfaces may be unaffected and can go dormant when fungicides are applied. The peak and valley terrain of porous substrates provide easy cover for micron-size spores eluding direct contact with viscid antimicrobial agents.”

The study concluded: “That the commonly used fungicides in the indoor environment cannot completely kill all the fungal inocula. Most of the fungi form dormant spores when exposed with fungicides. These dormant spores can germinate and resume growth when a favorable environment is available to them. The results provide further evidence that physical removal of indoor fungal contaminated material is necessary as a proper remediation practice when dealing with indoor air quality problems.”

Finally, harsh chemicals such as ozone, bleach, ammonia, and even many mold “killing” products can pose a health risk to your family because of the odors and chemical residues left behind.

A Look at Mold Remediation That Focuses on Removal

Mold remediation is often compared to the Wild West. In most states, the industry is largely unregulated, which means that widely different practices pass as “remediation.” While some remediation practices may be effective, many are insufficient or even unsafe.

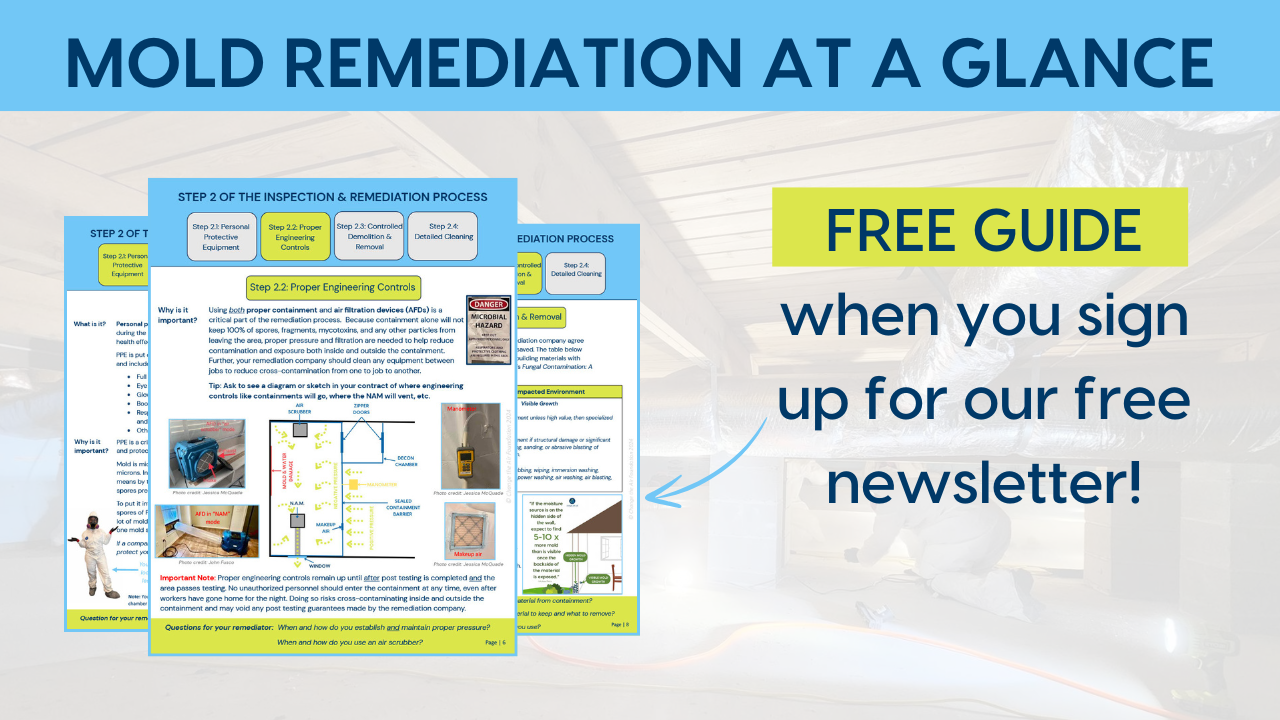

Mold remediation that focuses on safe and effective removal will not only address microbial growth above and below the surface but will also remove any byproducts that may have cross-contaminated the surrounding area. When it comes to remediation, harsh chemicals are rarely needed. In fact, when water and a surfactant (such as dish soap) are combined with proper engineering controls and procedures, remediation can be very effective. Learn more about safe and effective mold remediation using Step 2 of our “Start Here” feature, and download your free copy of “Mold Remediation At A Glance.”

According to the ANSI/IICRC S520 Mold Remediation Standards (2024)⁷:

“Physically removing mold contamination is the primary means of remediation. Mold contamination should be physically removed from the structure, systems, and contents. Attempts to kill, encapsulate, or inhibit mold instead of proper removal generally are not adequate. The Standard emphasizes source removal by physical methods, therefore, utilizing spray, fog, foam, gas, or other remediation approaches without physical removal, is a deviation from this standard of care.” [Section 1.4 Contamination Removal]

“Chemical treatments should not be used as a primary means to remove mold.” [Section 2 Mold Cleaners, Antimicrobial Chemicals, and Coatings as Remediation Tools]

“Mold-resistant coatings should not be used as ‘sealants’ or ‘encapsulants’ to contain or cover mold growth.” [Section 2.2.1 Coatings – Limitations of Use]

“Killing” mold is not very effective and neither is painting over it. Paints and encapsulants are often used to cover lazy or sloppy practices. Ironically, many of these products state they should only be used on clean and dry surfaces, or the warranty is void. If a surface is clean and dry, it doesn’t really need an encapsulant. Still, contractors and landlords are infamous for claiming that these products permanently trap mold and prevent the issue from returning. Unfortunately, encapsulants can fail (especially if moisture returns), and when that happens, mold can grow on top of and beneath the paint, making removal even more difficult and expensive.

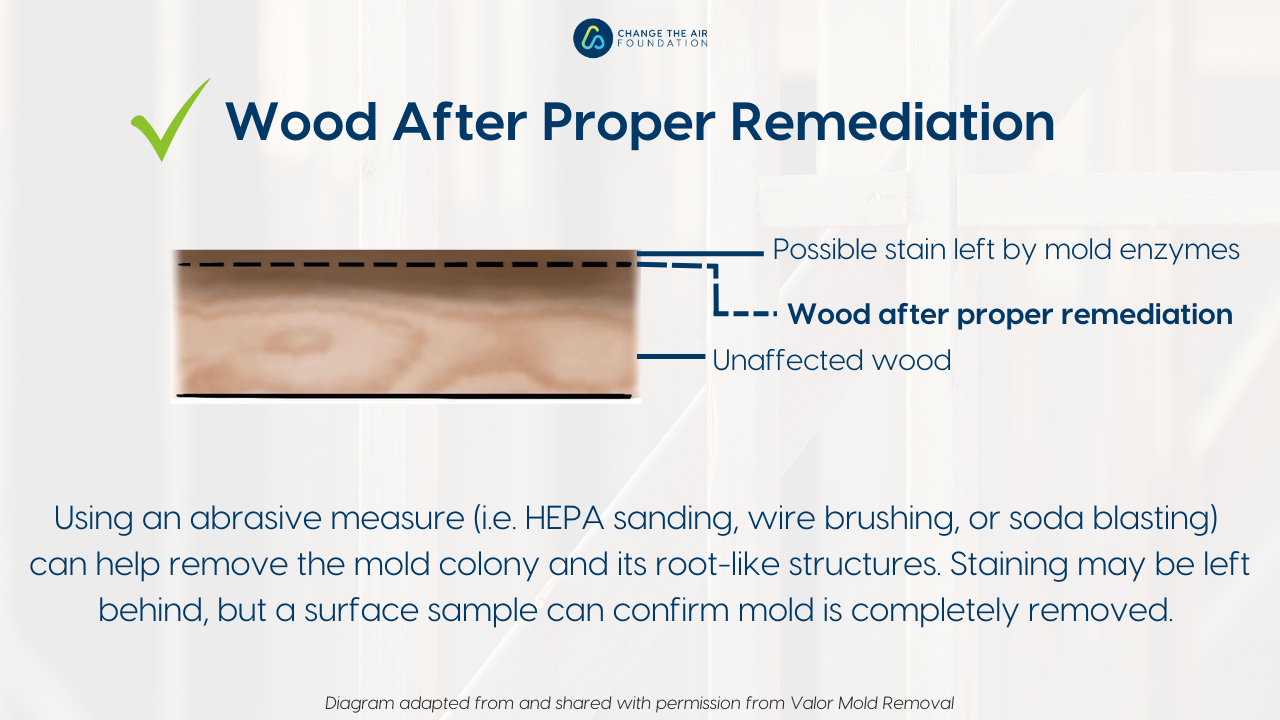

Some building materials–such as wood, plaster and concrete–can have mold growth physically stripped out using abrasive measures. Whereas, other building materials– such as carpet and drywall–must be replaced. The decision about what damaged materials to salvage and what to discard should be made by a knowledgeable Indoor Environmental Professional (IEP), remediation company, and the building occupant.

The table below provides a general overview of how to categorize building materials with mold growth and has been adapted and shared with permission from Michael Pinto’s “Fungal Contamination: A Comprehensive Guide to Remediation.”⁴ As a reminder, proper engineering controls and procedures should be in place before removing or remediating impacted material.

Assessment Chart for Contents From a Mold-Impacted Environment | |

Type of Material | Visible Growth |

Porous: fabric, paper, upholstered furniture, ceiling tiles, drywall, etc. | Disposal and replacement unless high value, then specialized restoration. |

Semi-porous: raw wood, studs, rafters, decking, unpainted cinder block, other masonry components, stucco, etc. | Disposal and replacement if structural damage or significant rot; scraping, scrubbing, sanding, or abrasive blasting of surface contamination. |

Non-porous: metal, plastic, glass, sealed wood, etc. | HEPA vacuuming, scrubbing, wiping, immersion washing, ultrasonic bath, power washing, air washing, air blasting, or steam cleaning. |

Before beginning any mold remediation, it’s important to start with a thorough investigation by a knowledgeable Indoor Environmental Professional (IEP). A qualified IEP will inspect the entire home from top to bottom including hard-to-reach areas such as attics, crawl spaces, and HVAC systems. The IEP should also provide a remediation plan tailored to what is safest and most effective for the homeowner or renter, not what is fastest, easiest, or cheapest for the remediation company. Unfortunately, not all IEPs are created equal, so it's important to thoroughly vet anyone before you hire them. Learn more about how to hire a knowledgeable IEP using Step 1 of our “Start Here” feature.

At a minimum, we recommend any mold remediation follow the ANSI/IICRC S520 Mold Remediation Standards (2024). Keep in mind these standards are still optional to follow in most states. The goal of any mold remediation should always focus on removal—never spraying, killing, covering up, or painting over it. Remember, certifications and standards are minimum starting points. Be sure to thoroughly vet any company before you hire them, and have a written remediation plan in place before work begins. Learn more about how to hire a knowledgeable remediation company using Step 2 of our “Start Here” feature, and be sure to download your free copy of “Mold Remediation At A Glance.”

Bottom line: No “spray and pray”! Mold remediation should always focus on safe and effective removal, never “killing.”

Next Steps for Homeowners and Renters:

1. Visit our “Start Here” section to get step-by-step support navigating the inspection and remediation process. Be sure to click “Read More” under each step.

2. Watch our video “Mold Remediation Part 1: Hiring the Right Team & Order of Events”

3. Download your free copy of “Mold Remediation At A Glance” by signing up for our free newsletter here.

References

Chakravarty, P., & Kovar, B. (2013). Evaluation of Five Antifungal Agents Used in Remediation Practices Against Six Common Indoor Fungal Species. Journal of Occupational and Environmental Hygiene, 10(1), D11- 16. https://doi.org/10.1080/15459624.2012.740987

U.S. Environmental Protection Agency (n.d.). Mold Course Chapter 1: Introduction to Molds. United States Environmental Protection Agency. Retrieved April 8, 2024, from https://www.epa.gov/mold/mold-course-chapter-1

Bennett, J. W., & Inamdar, A. A. (2015). Are Some Fungal Volatile Organic Compounds (VOCs) Mycotoxins? Toxins, 7(9), 3785–3804. https://doi.org/10.3390/toxins7093785

Pinto, M. A. (2008). Fungal Contamination: A Comprehensive Guide for Remediation (2nd ed.). Wonder Makers Environmental.

(2015, April). North America Gypsum Board Market By Type (Wallboard, Ceiling, Pre-decorated), By End-Use Industry (Residential, Institutional, Industrial, Commercial) & Region for 2026-2032. (Report ID 513149). Verified Market Research. https://www.verifiedmarketresearch.com/product/north-america-gypsum-board-market/

Anderson, B., Dosen, I., Lewinska, A. M., & Nielsen, K. F. (2017). Pre-contamination of new gypsum wallboard with potentially harmful fungal species. Indoor Air, 27, 6-12. https://knowthecause.com/wp-content/uploads/2017/02/Andersen2017WallboardNeosartyaChatomiumStachybotrys.pdf

Institute of Inspection Cleaning and Restoration Certification (2024). ANSI/IICRC S520 Standard for Professional Mold Remediation (4th ed.).